|

The Medical Polymers Group is led by Professor Lisa Pruitt in the Department of Mechanical Engineering at UC Berkeley. The lab primarily focuses on the wear properties of load bearing implantable medical devices such as artifical hips and knees.

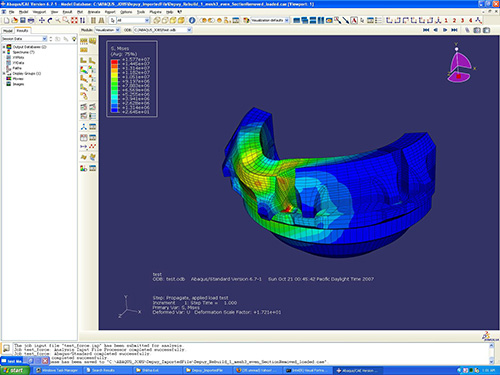

The FEA analysis was a project to analyze the failure of several types of artificial hips. Several devices were retrieved from patients and analyzed. These were each made of UHMWPE that had undergone a modern radiation treatment. We collected tensile and fatigue data on similar material samples. I reconstructed CAD models and meshes of the retrieved devices and applied our own sampled material properties and loading conditions to the components. We were in fact able to replicate the failure conditions. Short answer is that radiation treatment was affecting the brittleness of the material and causing greater fatigue induced crack propogation.

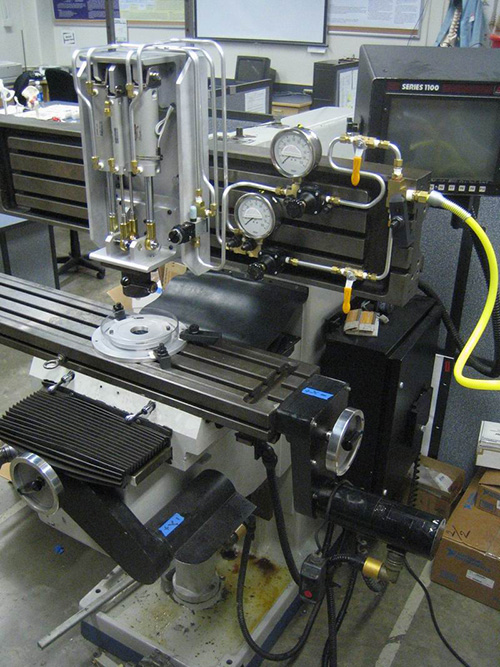

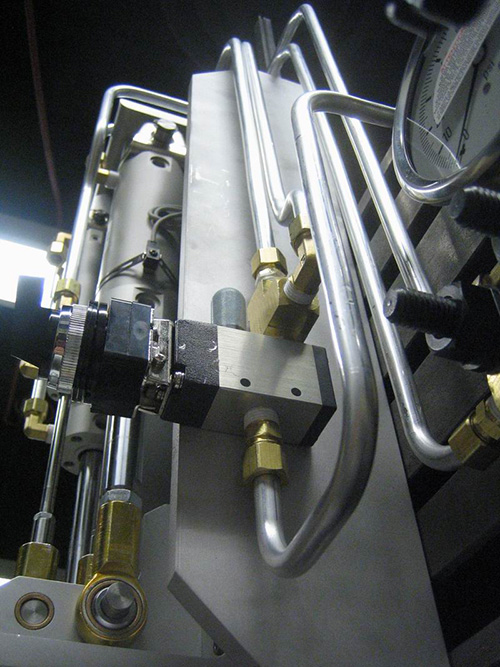

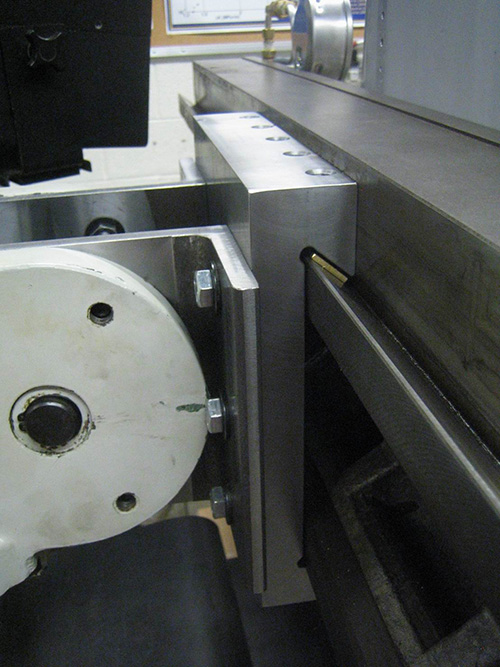

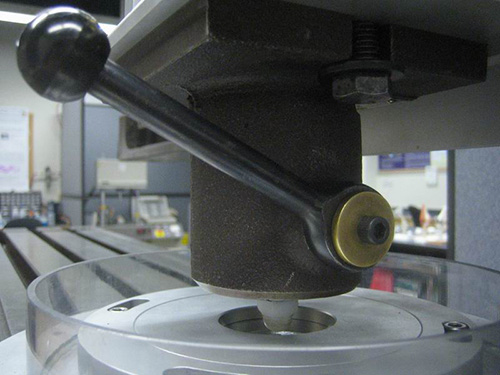

This is Elvis, a multi-degree-of-freedom pin-on-disk tribological testing machine. This project had been a grant proposal from a previous doctoral student and I picked it up along with a fellow graduate student, Eli Patten. The proposal was to retrofit a cnc milling machine into this sophisticated tribology inspection system. The system consists of an old cnc mill running an Anilam 1100 controller, a work table I scavenged from a machinery liquidator and a custom loading mechanism.

I did most of the design of this single degree of freedom loading mechanism while Eli focused on another two degrees of freedom that were later added. I also wrote a LabView based controller and user interface to control the machine and experiments. We shared the bulk of the machining along with two other undergraduate students. I layed out the process piping late one evening. An effort was made to use off-the-shelf components as much as possible.

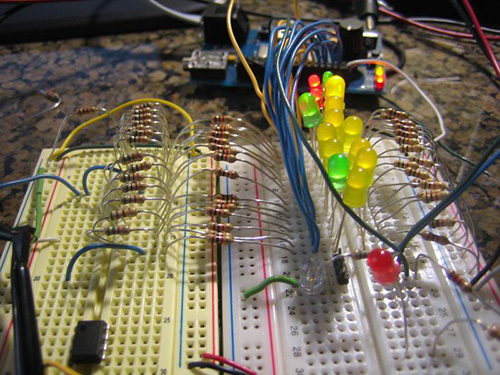

At one point a tachometer on the x axis failed. I prototyped a couple velocity estimating systems to trick the controller enough that I could continue development of the rest of the system until I could find a replacement tach. The picture below shows and R2R digital to analog converter and microcontroller velocity attempt. I also built a tach with a 555 timer with greater success.